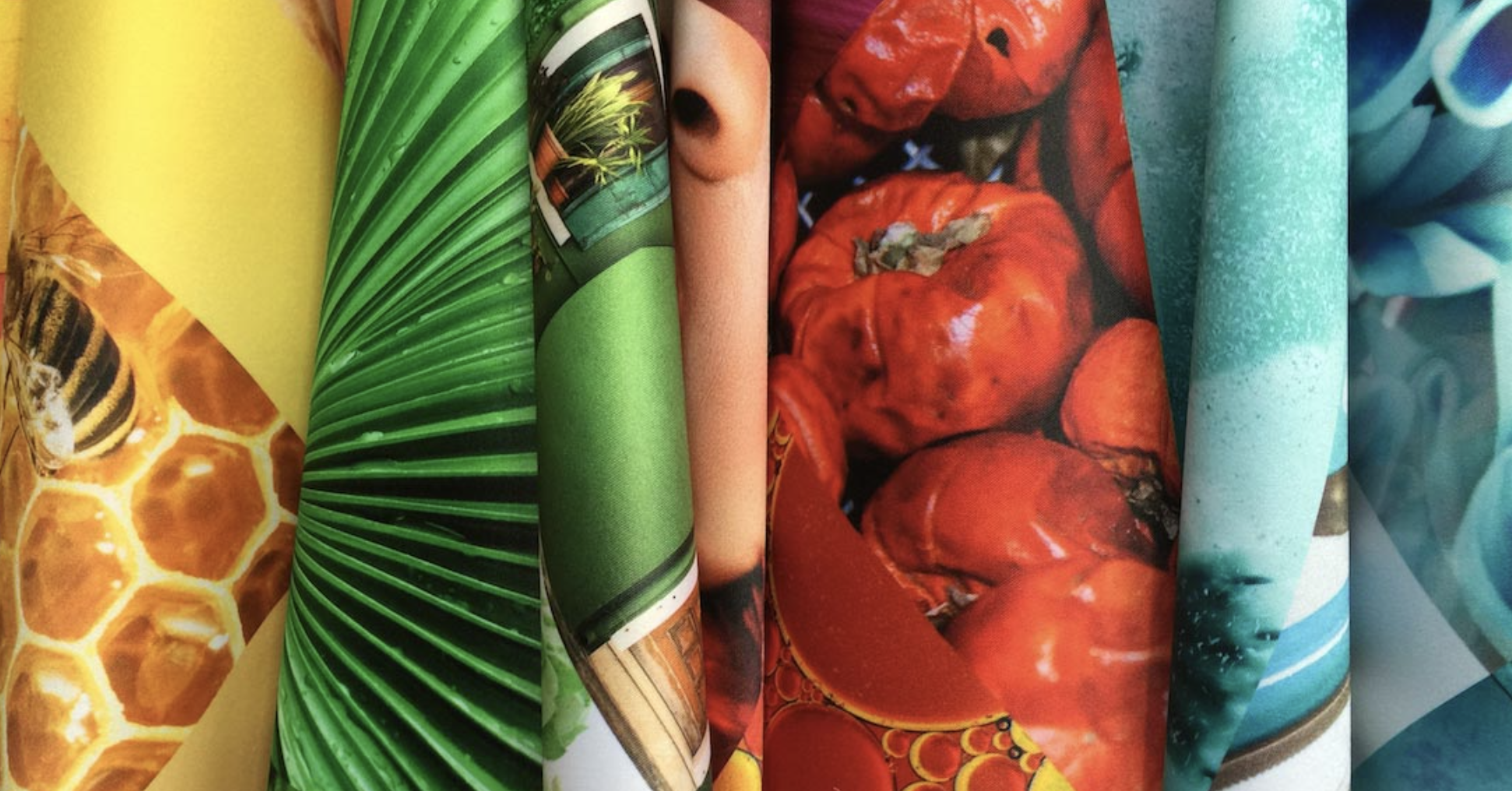

Sublimation printers use a heat transfer process to create high-quality, durable, fade-resistant prints that can be used for numerous substrates—from fabrics to ceramics. Sublimation printers transfer images from a special sublimation paper to the desired material, using pressure, time, and heat. These printers use dye sublimation ink, which turns into gas or vapor when transferred. The ink enters the “pores” of the material, then pressure activates the ink, which then becomes a part of the substrate and is embedded. Since sublimation printers don’t just place ink on top of the materials’ surfaces, they create a vibrant, smear-free output that doesn’t fade over time, even with repeated washings. This makes it an ideal solution to customize shirts, pillowcases, towels, mugs, and more.

Looking to purchase a sublimation printer? This article outlines some factors to consider while exploring your options, including user-friendliness, accuracy, the types of materials you want to customize, printing speed, and the types of inks you plan to use.

Marabu’s sublimation ink TexaJet DX-STE is ideal for both conventional transfer and direct printing on pre-treated polyester fabrics, offering flexibility for many commercial textile applications. Marabu sells replacement inks for Mimaki printers, which are less expensive but still high quality.

Once you’ve decided which printer to buy, Marabu is the best place to get sublimation inks. For more information about Marabu’s exceptional inks—and to get advice about your upcoming print projects—please contact us. You can receive more printer tips here.