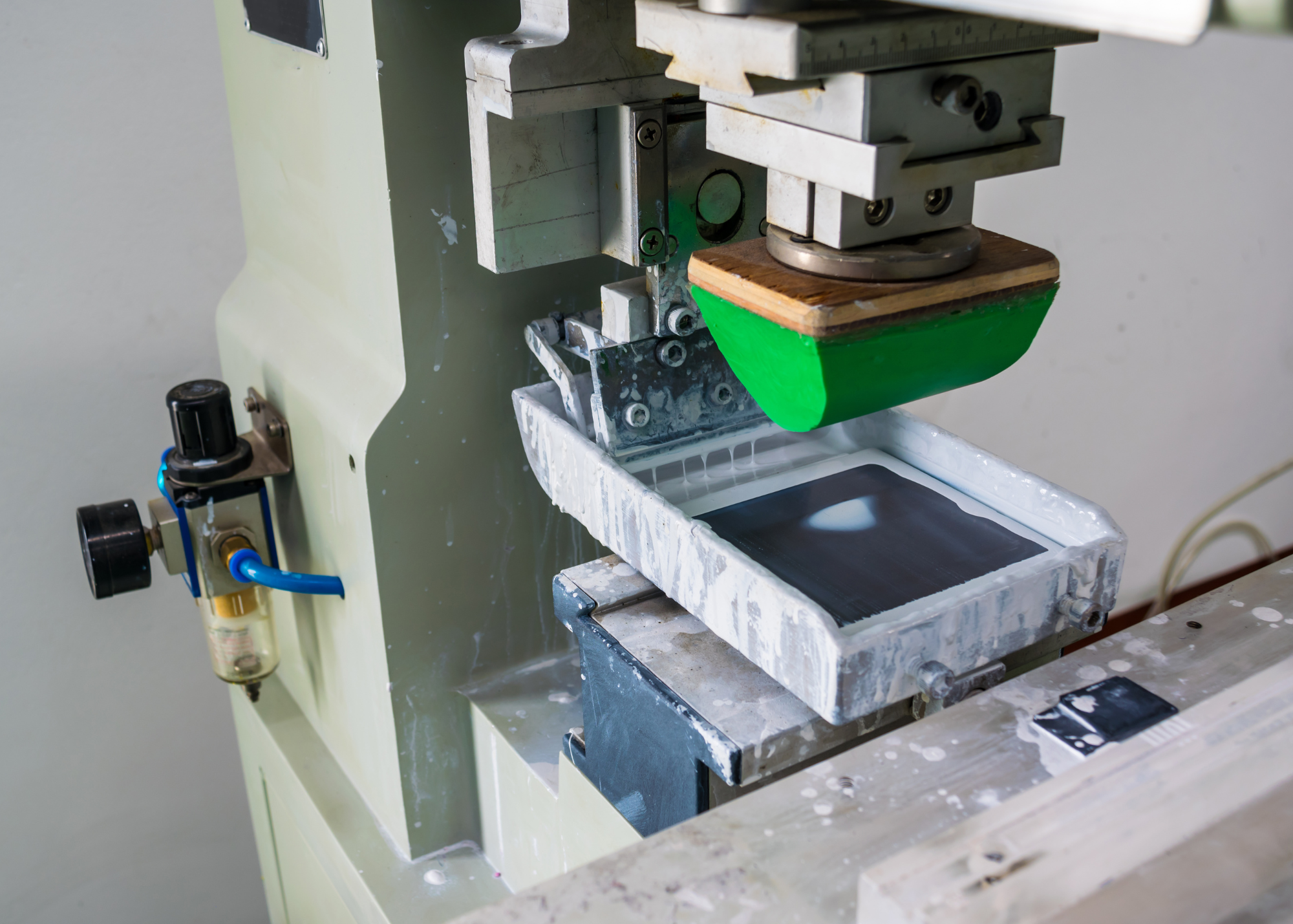

Products that have been printed by a pad printing process are so ubiquitous that we all encounter them multiple times throughout the day. The designs, the logos, the text that are featured on household items, sports apparel, childhood toys, and even automotive parts like speedometers are likely to have been printed by a pad printer. Professionals in the pad printing industry know fully well that out of all the parts that make up a pad printer — from the ink cups, the plates, and the pads — the pad printing inks are arguably the most critical component of the job. If you’re a pad printing professional and you’re looking to switch to a different pad printing ink, then you’ve already likely encountered a problem with the ink you’re currently using. In this article, we’ll explain what pad printing professionals should consider when they’re looking to switch to a different pad printing ink.

Pigment & the Importance of Consistency

When you are pad printing a batch of products for your clients, you know the importance of consistency in pigment and colors. An example we like to give is when you see a famous logo on a well-known sports apparel. In this example, their brand logo is an instantly recognizable white — no other white pigment will suffice for that job. When we typically think of the color white, one specific color comes to mind; it’s the color that we often see in printing paper and it has a certain crispness to it. In reality though, there are many variations of white colors. Depending on that color variation of white, some may have subtle hints of yellow, or even blue. We may not pay attention to the differences in white colors in most cases, but when it comes to certain brands, that color discrepancy will stand out. The importance of color consistency for any other brand holds true, whether it’s for a household item, a childhood toy, or any other consumer good.

Unfortunately, not all ink companies adhere to strict standards when it comes to their raw materials, leading to the inconsistency of pigment and color from one ink batch to another.

As one of the nation’s most trusted suppliers of pad printing inks, we at Marabu adhere to European standards for our pad printing ink series. Because European standards come with strict tolerances in terms of ink quality, we can guarantee that the ink batch you receive from us today will have the same quality three months from now — they won’t differ from batch to batch.

Adhesion to Different Substrates

It’s not uncommon for professionals in the pad printing industry to have a diverse portfolio of clients. One of your clients may be a provider of childhood toys that specializes in plastic interlocking bricks. Another one of your clients may be in the sports industry market that sells leather basketballs. In terms of adhesion, there really is no one single pad printing ink that works equally well for all the different types of substrates and materials. Printing on plastics requires a different pad printing ink than printing on leather basketballs. A given pad printing ink needs to be tailored to that specific substrate for the highest level of adhesion to occur — and that’s what Marabu specializes in.

At Marabu, we ask that you send a sample of your substrate to us, we then take your exact substrate into consideration and recommend the best pad printing ink for that job. We also incorporate lab testing along with a peel and scratch test to see if the logo, design, or text comes off; if the pad printing ink does not pass our peel and scratch test, then it’s back to the lab. We’ll continue to tailor the raw materials so your ink batch not only has the precise pigment you’re looking for, but also has strong adhesion to your specific substrate.

Health, Safety, & Environmentally Friendly

We live in an age where climate change and environmentally friendly initiatives are becoming an ever present concern. Unfortunately, not all ink companies take environmentally friendly initiatives into account when they’re creating their batch of inks, meaning ink batches that aren’t the safest for human health nor our planet.

At Marabu, we abide by ISO standards, which are an internationally recognized set of standards for quality control, health, safety, and environmental protection. We have a high interest in what kind of impact we have as ink manufacturers. We’re committed to giving our customers the highest quality ink while looking out for the future generations of our planet. And because we don’t deviate from the strict guidelines pertaining to our raw ingredients, each batch is formulated to be eco-friendly.

The Marabu Solution

If you’re a pad printing professional and work in the pad printing industry, you can rely on us to deliver on the promise of: quality, consistency, health, safety, and being eco-friendly. You’ll get all these elements from one ink batch to the next. In addition, you’ll get direct access to us for all the support you need, without having to go through an OEM or a third party. In fact, every single one of our ink batches has a unique code as part of a built-in verification process for traceability. Not only will we be able to identify and find the problem — if it were to occur — but we’ll also find a solution. Looking to switch to a different pad printing ink? Don’t hesitate to contact us today. You can also check out some more printing tips here.