It may be during a routine drive through the city streets or in the middle of being stuck in traffic, but regardless of location and time, cars adorned with those brightly colored vehicle vinyl wraps seem to stand out from the crowd — and they stand out with purpose.

Some vehicle wraps are there as a marketing strategy — like a billboard on wheels. Others treat vehicle wraps as an extreme sport in itself; the one with the most decked out car wins the prize. If you happen to be a NASCAR fan, then who can forget the dazzling introduction of the race car itself? Even NASCAR racers use vehicle wraps to captivate their spectators.

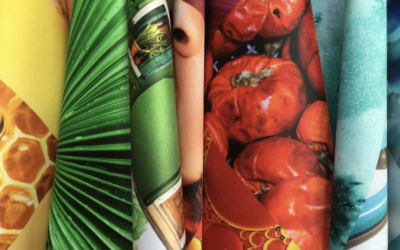

If you’re in the car decal printing and/or vehicle wrapping business, you probably have a diverse portfolio of clients. It may be someone who wants to change their car’s current color scheme, or someone who wants to demonstrate their patriotic pride by having a flag design on one of the windows. Some of your customers may want to embellish their car with various designs and logos and give their car more personality. You may even have a race car driver as a client. Regardless of design, there’s certain practical tips you can incorporate so that the end product is as polished as possible. With these tips, your clients will be able to show off their cars without having to say a word.

Eco-solvent inks for Roll-to-Roll Printers

There’s many benefits to using Roll-to-Roll printers for vehicle wraps. Roll-to-Roll printers allow for large printing jobs which is more than sufficient for vehicle wraps — even bus wraps! Afterall, the standard dimensions of any given part of a car is larger than most commonly printed on items such as household goods. Roll-to-Roll printers can handle this high demand in output.

With Roll-to-Roll printers, you also get a continuous feed in printing with less interruptions which results in a quicker turnaround. With this type of printer, your vinyl car wrap business will be able to handle the high volume of car wraps being printed.

When it comes to industry favorites for Roll-to-Roll printers, this Mimaki one has an established presence as a creative must-have tool. As you may already be aware, Roll-to-Roll printers require a certain type of inks in order for the ink to stick to that given substrate. For your vehicle wraps, our Ultra Jet series and Mara Jet series are specifically tailored for complex printing jobs done on Roll-to-Roll printers.

Coatings for Textured Surfaces

The world of vinyl car wraps have become increasingly creative as designers incorporate new textures and designs. Textured car wraps give a customized look to the car without the need for a new paint job. There are many types of textured car wraps out there which include:

- Perforated mesh

- Carbon fiber

- Brushed aluminum

- Hexis Gloss

- Brushed titanium

A special consideration to keep in mind is to have a protective coating for your textured car wraps. They don’t have the typical film laminate layer over the print. Textured car wraps by nature are meant for outdoor use, meaning they will be exposed to heavy wear and tear from a wide variety of factors. UV rays can cause the textured vehicle wrap to crack in some places and for the ink to fade. Parking in the shade as much as possible can go a long way in protecting the car wrap from excessive sun exposure, but selecting a durable protective coating that can withstand the UV rays is one of the best ways to make sure the textured vinyl car wrap remains looking fresh. Our Marabu ClearJet can be applied to any textured car vinyl wraps such as perforated vinyl art and window graphics.

Tips for Installing a Car Wrap

The installation of a car wrap is a highly technical process. There are many curves, edges, and shapes to a vehicle and if a car wrap doesn’t conform to the shape of the car precisely, the overall design can appear messy. One has to be sensitive to the amount of pressure applied to any given area otherwise bubbles may appear underneath the surface.

For this reason, it’s best to leave the installation of a car wrap to a trusted professional. However, for the DIY enthusiasts, there are many tutorials available on how to install a vinyl car wrap. Remember, learning to wrap a car doesn’t happen overnight, and can take trial and error.

For the tech-savvy, there are software programs that design car wraps in precise specifications for any given vehicle. Using a software program, and getting the right specifications, leads to a smoother installation.

Last, but not least, applying a vinyl application fluid, such as our Splash vinyl application fluid, can make the very installation of a car wrap smooth and efficient. By applying a vinyl application fluid, the wrap can be shifted into place before squeegeeing smooth. Don’t worry, it will not lose any tack and stick to the car’s surface seamlessly. And if the car’s owner changes his or her mind, and decides to remove their wrap, they can feel rest assured that there was no damage done to the vehicle’s surface paint.

Have any questions regarding car wrap solutions? Please reach out to us for more information. We look forward to helping you with your project. You can also check out some of our favorite printing designs here.