Advantages of Using UV Ink to Print on Glass, Plastic, Metal, and 3D Objects

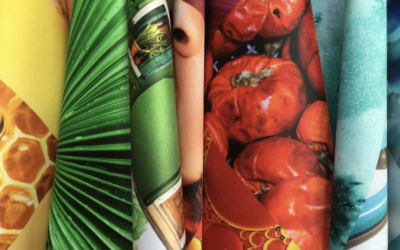

Printing with UV ink offers endless – and exciting – opportunities. UV printing has evolved and advanced recently, and now a wide range of substrates can be printed on with UV ink using a flat, cylindrical or 3D printer. Printing shops can successfully use UV inks on everything from a glass wine bottle to a wooden cornhole game board.

According to Syd Northup, Vice President of Sales, at Marabu Ink North America, printing shops are using UV printing to customize:

- Glass – Whether your clients want a design on a wine bottle or their logo on a shot glass, you’ll get excellent results with UV ink. In fact, it’s possible to print a full digital image from the top to the bottom of a wine (or other) bottle, helping your clients make a statement on a crowded store shelf. While commemorative glasses – such as shot glasses from a souvenir shop or personalized pint glasses at a brewery – are often screen or pad printed, UV printing offers another viable and durable option.

- Cylindrical and 3D objects – With recent technological advancements, you can use UV inks on a wide range of cylindrical objects, including metal, plastic, and glass. Use UV printing to customize cups, bottles, mugs, jars, vases – and even lipstick tubes.

- Stainless steel – UV ink is ideal for printing on stainless steel, which is a difficult substrate to customize. UV printing has grown significantly in the promotional products space, and is becoming a more common approach to personalize pens, tins, coasters, travel coffee mugs, and more. Increasingly, we’re seeing UV inks being used to print on credit cards using a small, flat machine. This method is also perfect to print on metal “elite status” cards, such as the ones used for hotel and airline VIP Clubs.

- Signs and more – Not only are we seeing a spike in UV printing for signs, but it’s exciting to see print companies using UV inks in unique ways, such as customizing wood cornhole boards in college colors, with designs like sports team logos. Traditionally, companies would paint products like cornhole boards by hand, which makes it difficult to produce large quantities or consistent artwork. Or they’d print with an overlay on vinyl, which doesn’t adhere to wood very well and could easily peel off and look messy and unprofessional. In contrast, UV inks look fantastic – and are durable – on these wood boards. The UV inks are cured by LED or mercury lamps and are formulated to dry instantly.

- Sports equipment – Another fun development is using UV printing on sports equipment, such as hockey pucks, golf grips, and balls. This allows your clients – from professional sports teams to amateur rec leagues – to easily personalize their equipment to reflect their brands.

Northup outlined key benefits of using UV printing and UV inks, including:

- The number of substrates you can print on. Our partners are successfully using Marabu’s UV inks to customize many types of products, from hockey pucks to whiskey bottles.

- The ability to print on a variety of thicknesses. Printing professionals can use UV inks on anything from an inch to four inches, making it flexible for a variety of projects.

- It adheres as you’re printing. Using LED or mercury lights to cure the inks, they dry in an instant and are ready immediately.

- The colors are amazing. There have been tremendous advancements in UV inks and there’s a wide range of spectacular colors that are sure to help your clients’ products get noticed.

- It’s become more affordable. The cost for UV printers is less expensive now, making it a more viable option for printing businesses.

Marabu has a wide variety of high-quality ink sets for many different UV printers. Our UV inks offer the most superior adhesion in the industry and deliver excellent results in terms of adhesion, opacity, versatility, reactivity, and degree of gloss. Check out our wide portfolio of UV ink options and contact us for more information. You can receive more printing tips here.